Welcome to Epoch International, your trusted provider of top-tier Oil, Gas Equipment & Safety Products. At Epoch International, we specialize in delivering high-quality equipment tailored to the unique demands of the oil and gas industry, coupled with a comprehensive range of safety products to ensure the well-being of your workforce. Oil, Gas Equipment: Explore our extensive inventory featuring cutting-edge equipment designed for the oil and gas sector. We provide a diverse range of solutions, meticulously curated to meet the industry's stringent requirements. From drilling and extraction to processing and transportation, our equipment is engineered for reliability and efficiency. Safety Products: At Epoch International, safety is our priority.

We offer a comprehensive selection of safety products designed to protect your workforce and enhance operational safety. Our range includes personal protective equipment (PPE), safety gear, and advanced safety technologies to mitigate risks and ensure a secure working environment. Epoch International is committed to being your reliable partner in the oil and gas industry. Explore our Oil, Gas Equipment & Safety Products to elevate the efficiency and safety standards of your operations. Contact us today for customized solutions that align with the unique needs of your projects.

Industrial automation is the use of control systems, such as computers or robots, and information technologies for handling different processes and machinery in an industry to replace a human being. It is the second step beyond mechanization in the scope of industrialization. Increase Quality and Flexibility in Your Manufacturing Process Earlier the purpose of automation was to increase productivity (since automated systems can work 24 hours a day) and to reduce the cost associated with human operators (i.e. wages & benefits). However, today, the focus of automation has shifted to increasing quality and flexibility in the manufacturing process.

In the automobile industry, the installation of pistons into the engine used to be performed manually with an error rate of 1-1.5%. Presently, this task is performed using automated machinery with an error rate of 0.00001%. Advantages of Industrial Automation Lower operating cost: Industrial automation eliminates healthcare costs and paid leave and holidays associated with a human operator. Further, industrial automation does not require other employee benefits such as bonuses, pension coverage, etc. Above all, although it is associated with a high initial cost it saves the monthly wages of the workers which leads to substantial cost savings for the company. The maintenance cost associated with machinery used for industrial automation is less because it does not often fail. If it fails, only computer and maintenance engineers are required to repair it. High Productivity Although many companies hire hundreds of production workers for up to three shifts to run the plant for the maximum number of hours, the plant still needs to be closed for maintenance and holidays. Industrial automation fulfills the aim of the company by allowing the company to run a manufacturing plant for 24 hours a day 7 days a week and 365 days a year. This leads to a significant improvement in the productivity of the company. High Quality Automation alleviates the error associated with a human being. Further, unlike human beings, robots do not involve any fatigue, which results in products with uniform quality manufactured at different times. High Flexibility Adding a new task in the assembly line requires training with a human operator, however, robots can be programmed to do any task. This makes the manufacturing process more flexible. High Information Accuracy Adding automated data collection can allow you to collect key production information, improve data accuracy, and reduce your data collection costs. This provides you with the facts to make the right decisions when it comes to reducing waste and improving your processes. High Safety Industrial automation can make the production line safe for employees by deploying robots to handle hazardous conditions.

Welcome to Epoch International, a global leader in Variable Frequency Drive (VFD) solutions. At Epoch International, we take pride in being your one-stop solution for VFD needs, representing major industry-leading brands including Siemens, ABB, Mitsubishi, Allen Bradley, Schneider, and more. Global Supply: Epoch International's global presence allows us to serve customers around the world with a comprehensive range of VFD products from the most reputable brands. Whether you're looking for Siemens precision, ABB reliability, Mitsubishi innovation, Allen Bradley performance, Schneider efficiency, or any other leading brand, we've got you covered.

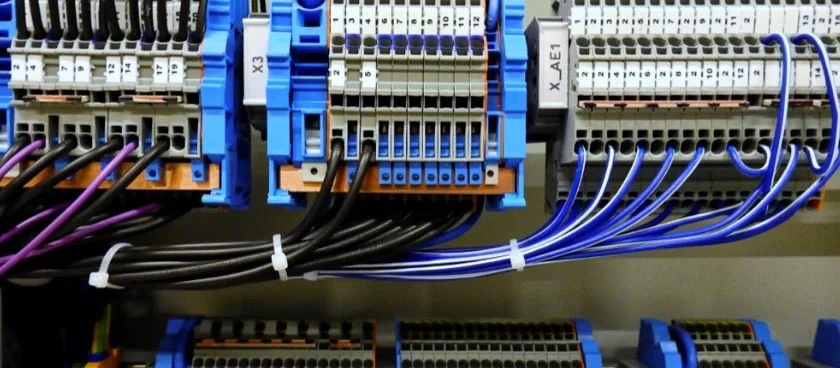

Regional Expertise - MENA Region: While our reach extends globally, we understand the importance of regional expertise. In the Middle East and North Africa (MENA) region, we specialize in delivering tailored VFD solutions that align with the specific requirements of the local industrial landscape. Epoch International is committed to providing you with the highest quality VFD products and services, ensuring seamless integration into your operations. Contact us today to experience the Epoch International difference with the best brands in the industry. While commissioning the VFD make sure the starter panel installation is complete and make sure that there is no damage in the starter panel. If any component is damaged then it must be repaired. Check the details of the insulation resistance values of the incoming and outgoing power wiring. Make sure that all the BMS wiring is finished. We must also check the cable dressing inside the starter panel. Make sure all the control wiring is done properly. Make sure the ratings of MCB, MCCB, and fuses are correct. All the wiring termination must be checked. We must check all the earthing connections and supporting insulators. The phase sequence and incoming voltage must be checked. The operations of the selector switch and pushbuttons must be checked. Check the speed limit and direction of rotation of the motor. Before switching the incomer on we must check the incoming voltage and phase sequence. Control supply must be checked and also check the bypass starter operation with the motor disconnected. The operation of VFD must be checked after disconnecting the motor. In the automobile industry, the installation of pistons into the engine used to be performed manually with an error rate of 1-1.5%. Presently, this task is performed using automated machinery with an error rate of 0.00001%. Advantages of Industrial Automation Lower operating cost: Industrial automation eliminates healthcare costs and paid leave and holidays associated with a human operator. Further, industrial automation does not require other employee benefits such as bonuses, pension coverage, etc. Above all, although it is associated with a high initial cost it saves the monthly wages of the workers which leads to substantial cost savings for the company. The maintenance cost associated with machinery used for industrial automation is less because it does not often fail. If it fails, only computer and maintenance engineers are required to repair it. High Productivity Although many companies hire hundreds of production workers for up to three shifts to run the plant for the maximum number of hours, the plant still needs to be closed for maintenance and holidays. Industrial automation fulfills the aim of the company by allowing the company to run a manufacturing plant for 24 hours a day 7 days a week and 365 days a year. This leads to a significant improvement in the productivity of the company. High Quality Automation alleviates the error associated with a human being. Further, unlike human beings, robots do not involve any fatigue, which results in products with uniform quality manufactured at different times. High Flexibility Adding a new task in the assembly line requires training with a human operator, however, robots can be programmed to do any task. This makes the manufacturing process more flexible. High Information Accuracy Adding automated data collection can allow you to collect key production information, improve data accuracy, and reduce your data collection costs. This provides you with the facts to make the right decisions when it comes to reducing waste and improving your processes. High Safety Industrial automation can make the production line safe for employees by deploying robots to handle hazardous conditions.

Welcome to Epoch International, your trusted partner for cutting-edge Programmable Logic Controller (PLC) solutions. At Epoch International, we bring you a comprehensive array of PLC products, proudly representing major industry-leading brands such as Siemens, ABB, Mitsubishi, Allen Bradley, Schneider, and more. Global Supply: Epoch International's global footprint ensures that we can meet your PLC needs anywhere in the world. We provide a diverse range of PLC solutions, each crafted to perfection by renowned brands like Siemens, ABB, Mitsubishi, Allen Bradley, Schneider, and others. No matter your location, our global supply network ensures prompt delivery and exceptional service. Regional Expertise - MENA Region: While we serve customers globally, our specialization extends to the Middle East and North Africa (MENA) region.

Epoch International understands the nuances of the MENA industrial landscape, offering tailored PLC solutions that align seamlessly with regional requirements. Epoch International is committed to delivering the highest quality PLC products and services, ensuring optimal efficiency in your industrial processes. Explore the excellence of Siemens precision, ABB reliability, Mitsubishi innovation, Allen Bradley performance, Schneider efficiency, and more. Contact us today to experience the Epoch International difference with the finest brands in the PLC industry.

We supply all kinds of HMIs for Industrial Applications. A Human-Machine Interface (HMI) is a user interface or dashboard that connects a person to a machine, system, or device. While the term can technically be applied to any screen that allows a user to interact with a device, HMI is most commonly used in the context of an industrial process. A Human-Machine Interface (HMI) is a user interface or dashboard that connects a person to a machine, system, or device. While the term can technically be applied to any screen that allows a user to interact with a device, HMI is most commonly used in the context of an industrial process. Although HMI is the most common term for this technology, it is sometimes referred to as Man-Machine Interface (MMI), Operator Interface Terminal (OIT), Local Operator Interface (LOI), or Operator Terminal (OT).

HMI and Graphical User Interface (GUI) are similar but not synonymous: GUIs are often leveraged within HMIs for visualization capabilities. In industrial settings, HMIs can be used to: Visually display data Track production time, trends, and tags Oversee KPIs Monitor machine inputs and outputs And more Similar to how you would interact with your air-conditioning system to check and control the temperature in your house, a plant-floor operator might use an HMI to check and control the temperature of an industrial water tank, or to see if a certain pump in the facility is currently running. HMIs come in a variety of forms, from built-in screens on machines, to computer monitors, to tablets, but regardless of their format or which term you use to refer to them, their purpose is to provide insight into mechanical performance and progress. HMI technology is used by almost all industrial organizations, as well as a wide range of other companies, to interact with their machines and optimize their industrial processes. Industries using HMI include: Energy Food and beverage Manufacturing Oil and gas Power Recycling Transportation Water and wastewater And many more The most common roles that interact with HMIs are operators, system integrators, and engineers, particularly control system engineers. HMIs are essential resources for these professionals, who use them to review and monitor processes, diagnose problems, and visualize data.

We supply for all kinds of Project expertise bulk purchases of products like Instrumentation Bulk Material Package, Instrumentation Fittings, Tubes, Pd Meters, Flowmeters, Shades For Instruments, Rupture Discs, Flame Arresters, Corrosion Coupon / Probe, Retrieval Tools, Chemical Injection Quill, Pipeline Strainers And Filters, Studs, And Bolts, Fire Protection Equipments Ul / FM, Workshop Tools And Tackles

Welcome to Epoch International, your go-to destination for reliable Bearings solutions. At Epoch International, we specialize in providing a diverse range of high-quality bearings tailored to meet the demands of various industries. Bearing Solutions: Explore our extensive inventory, which includes a wide selection of bearings designed for efficiency and durability. From ball bearings to roller bearings, our Bearings division offers comprehensive solutions for a variety of applications. We proudly feature products from major industry leaders such as SKF, Schaeffler, Timken, NSK, NTN, JTEKT, IKO Nippon Thompson, Nachi-Fujikoshi, and more. Our commitment is to provide products that ensure smooth operations, reduce friction, and enhance the reliability of your machinery. Global Reach: With a global presence, Epoch International caters to clients worldwide with superior bearing solutions. Whether you are in manufacturing, automotive, or any industry that relies on precision machinery, our Bearings division is equipped to meet your specific needs. Epoch International is dedicated to being your trusted partner in the bearing industry. Explore our Bearings division to find innovative solutions that elevate the performance and longevity of your machinery. Contact us today for personalized bearing solutions that align with your unique requirements.